- Home

-

Masks, Fins

We recommend:xDeep RADICALzł320.00Tusa PARAGON optical "-"zł799.00EX1 - JET finszł399.00LightJet - lightweight finszł518.54

Masks, Fins

We recommend:xDeep RADICALzł320.00Tusa PARAGON optical "-"zł799.00EX1 - JET finszł399.00LightJet - lightweight finszł518.54 -

Regulators

Regulators

-

BCD Wings

BCD Wings

-

Gauges

Gauges

-

Suits

Suits

-

Accessories

Accessories

-

Service

Service

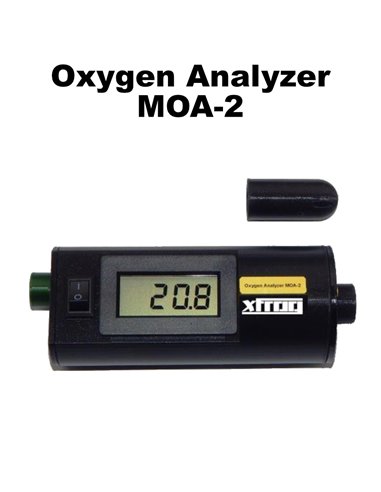

Nitrox MOA-2 Analyzer

xFrogAnalyzer with R-17VAN external sensor on cable. Powered by a 9V battery. Includes plug, flow tee and resealable package.

custom html

We ship worldwide

Shipping within 48 hours

We have a loyalty program

We care about the safety of shipments

The simplest example of using analyzers in diving is to measure the O2 content of a Nitrox or Trimix cylinder before a dive.

The analysis is done by bringing the sensor close to the loosened valve at the cylinder for a few seconds and reading the result on the display.

The valve should be unscrewed slightly, maintaining a constant flow of about 2-4 l/min and making sure that the flowing pressurized mixture (and other debris from the cylinder) does not damage the delicate cathode inside the sensor. Another solution is an additional plastic tee attached to the valve or screwed into the cylinder valve (DIN), to which only the sensor is connected (angularly) or a special flow restrictor that guarantees a constant flow regardless of the gas pressure in the cylinder.

Before the analysis you always need to calibrate the analyzer, preferably on the cylinder, in which there is 100% O2, or if you do not have such in the field conditions calibrate assuming that in the atmospheric air at sea level there is 20.9% O2.

Analyzers are delicate devices and need to be protected from moisture, low and high temperatures and shocks.

On the other hand, the sensors themselves, when they are not working, it is good to disconnect them from the analyzer and protect them with a special plug, then their service life can reach up to 36 months.